Table of Contents

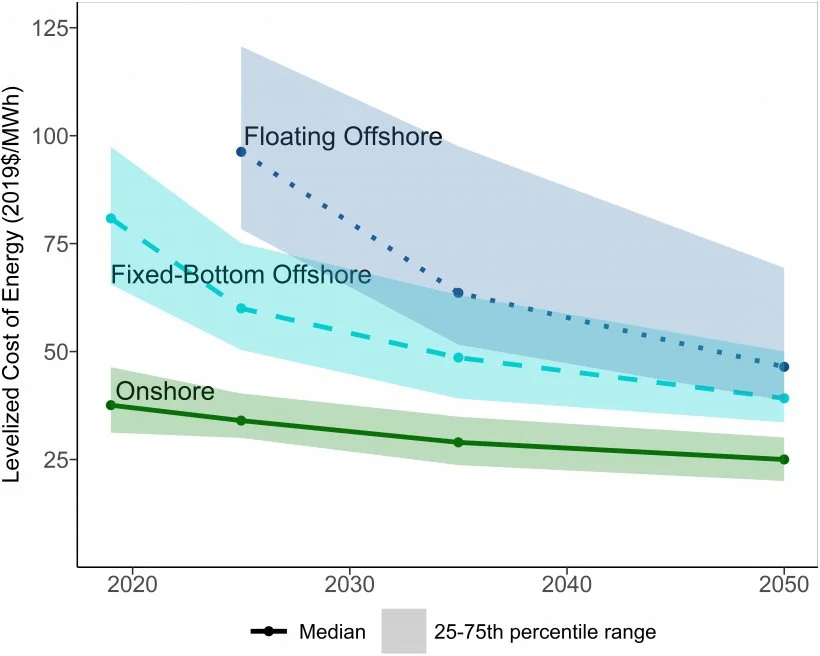

The total cost of offshore wind farms has steadily declined over the past decade, making this renewable energy source increasingly competitive with traditional electricity generation methods. According to the latest data, the current fixed-bottom offshore wind cost estimates are USD 95 per megawatt-hour (MWh), and floating offshore wind costs USD 145/MWh.

Recent projections suggest that the average levelized cost of energy (LCOE)—the lifetime cost of a power plant divided by its overall energy production—could further decrease from USD 75/MWh in 2021 to USD 53/MWh by 2035 for fixed-bottom offshore wind energy. The LCOE is expected to drop even more significantly for floating offshore wind energy, from USD 207/MWh in 2021 to USD 64/MWh in 2035.

To understand cost decrease over the past ten years, let's examine five key factors that influence offshore wind farm costs:

- Turbine Technology and Size

- Site Conditions and Water Depth

- Construction and Installation cost

- Operation and Maintenance

- Financing and Regulations

Turbine Technology and Size

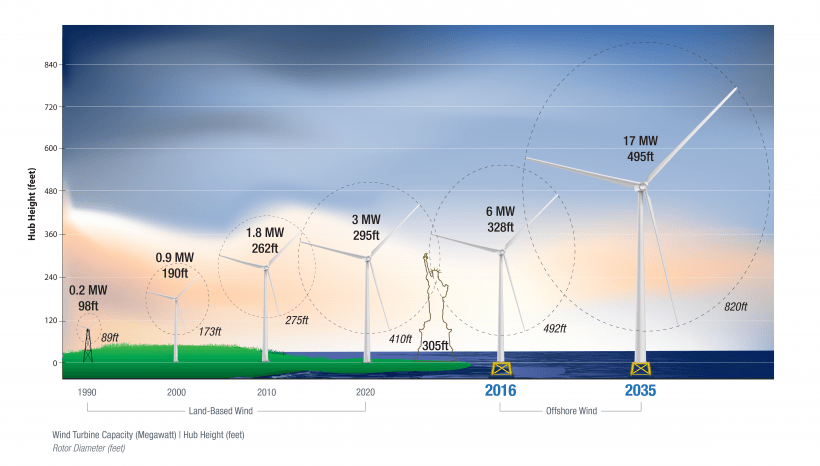

Offshore wind turbine technology has advanced over the past decade, resulting in larger and more efficient turbines that have helped to reduce the cost of offshore wind farms. The increased rotor blade size allows turbines to capture more wind energy, generating more electricity. Larger turbines, such as the GE Haliade-X with a capacity of 12 MW and blades 107 meters long, and the Siemens Gamesa SG 14-222DD with an offshore wind capacity of 15 MW, exemplify the trend towards fewer but larger turbines.

Offshore Turbine Technology

The advancements in turbine technology have enhanced the energy efficiency and scalability of wind power generation. Modern turbines are designed with advanced materials and engineered aerodynamically to maximize energy capture from wind. The GE Haliade-X, for instance, is notable for its size and technological innovations, including digital controls and advanced materials that improve durability and efficiency. Similarly, Siemens Gamesa's SG 14-222DD has technological features that allow for greater clean energy output with fewer turbines, having a rotor diameter of 222 meters.

Turbine Size

The trend towards larger turbine sizes has significant implications for both the energy cost and layout of offshore and onshore farms. Larger wind turbines can capture more wind energy to small wind turbines, generating more electricity from the same wind resource. However, larger turbines come with higher initial energy costs, with a typical offshore wind turbine cost between USD 2.6 and USD 4 million. The average selling price for Nordex turbines in 2023 was about USD 965,000 per MW. Despite the steep upfront investment, wind farms' operational complexity and overall construction costs can be reduced by deploying fewer, larger turbines.

The spacing of turbines is another critical factor influenced by their size. Wind turbines are generally spaced at four times their rotor diameter to avoid interference and maximize efficiency. This spacing ensures that the turbines do not disrupt each other's wind flow, essential for maintaining optimal power output. More giant turbines, which have bigger rotor diameters, require more space. This need for increased spacing can impact a wind farm's layout and total wind power capacity, potentially increasing area costs. The larger turbines' enhanced efficiency and higher energy production often justify these additional spatial requirements.

Site Conditions and Water Depth

Site conditions and water depth are other two critical factors influencing the cost of offshore wind farms. According to a 2020 survey, the average annual wind speed for new offshore wind projects will decline from 7.9 m/s in 2019 to 7.5 m/s by 2035. This decline is attributed to the initial selection of higher-wind-speed areas, pushing newer projects to less favorable locations.

Fixed-Bottom Offshore Wind Farms

Fixed-bottom offshore wind farms are predicted to be located further from shore—70 km in 2035 compared to 40 km in 2019—and in deeper waters, increasing from 30 meters in 2019 to 42 meters in 2035. Despite these more challenging site conditions, the anticipated increase in turbine size and capacity is expected to maintain wind project viability. For instance, the median offshore wind project size for fixed-bottom offshore wind farms is projected to grow significantly, from 500-699 MW in 2019 to 900-1,299 MW in 2035.

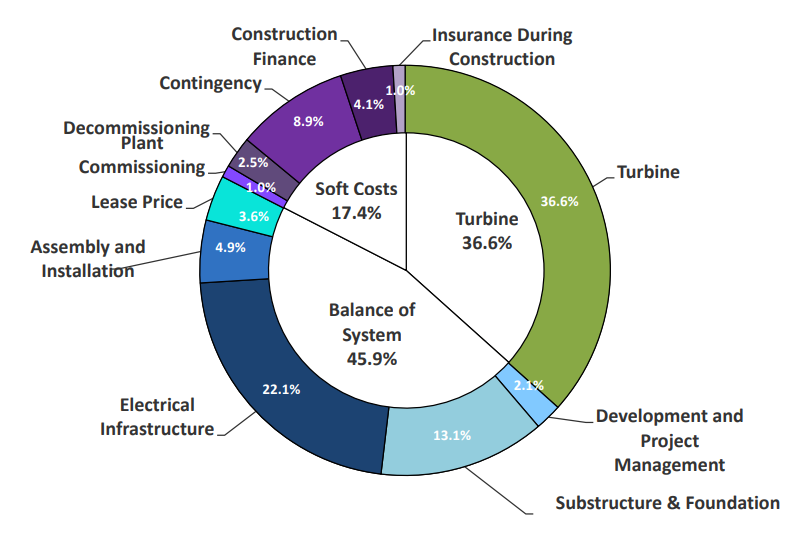

Fixed-Bottom Offshore Wind System CapEx Component Cost Breakdown

Source: nrel.gov

The annual average wind speed for fixed-bottom projects is expected to remain stable at 9.5 m/s at 100 meters above water. This stability suggests that moving projects further offshore will not compromise wind quality, especially as larger turbines with higher hub heights can access more stable and stronger wind currents. The advancements in turbine technology, coupled with the increased size, help to balance the more challenging site conditions, maintaining overall energy capture and project efficiency.

Floating Offshore Wind Farms

Though smaller in scale compared to fixed-bottom setups, floating offshore wind power projects are forecasted to face even more challenging site conditions. By 2035, the typical floating offshore wind project is expected to be situated 100 km from shore, in water depths ranging between 100 and 199 meters, and to experience higher annual average wind speeds of 10 m/s at 100 meters above water. This is compared to fixed-bottom projects that maintain an annual average wind speed of 9.5 m/s at the same height.

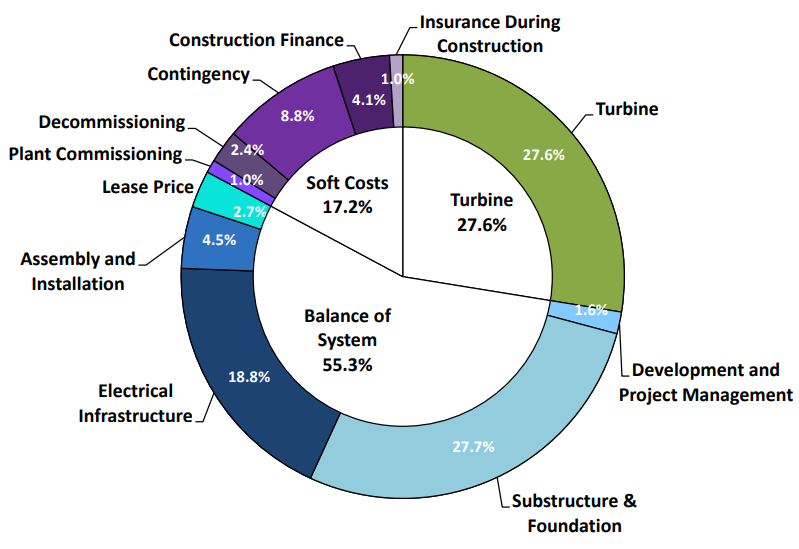

Floating Offshore Wind System CapEx Component Cost Breakdown

Source:nrel.gov

Floating wind turbines are expected to become cost-competitive, with fixed-bottom installations at water depths exceeding 60 meters by 2035, a reduction from the 80 meters noted in 2019. This anticipated cost reduction is likely due to advancements in floating turbine technology and economies of scale. Adopting floating foundations is expected to grow, with experts predicting that 11-25% of new offshore wind projects globally will feature floating structures by 2035.

Construction and Installation

The construction and installation phases are crucial in determining the overall cost of offshore wind farms. Advancements in turbine technology and installation methods have reduced offshore wind farm costs over time.

Construction Costs

Construction costs entail the capital expenditures in designing, setting up, and installing a new wind farm. Recent advancements in turbine technology have influenced these costs, and the construction time for 1 MW of installed capacity in offshore wind energy decreased by 71% from 2000 to 2017, mainly due to the increase in turbine capacity from 3 MW to 10-12 MW. This scalability means fewer turbines are needed, reducing the building materials required for their foundations.

With wind turbines with capacities of up to 12 MW, the overall construction costs can be lower. Larger turbines mean fewer units to install, translating to less foundation material and reduced construction complexity. Reducing the number of turbines needed for the same energy output contributes to significant savings. By 2024, the cost of building wind farms is expected to be reduced by a quarter, aiding in the continued decline of offshore electricity prices.

Installation Costs

Installation costs are another critical factor in the economics of offshore wind farms. Modern offshore wind turbines require complex and specialized installation processes. Wind turbine installation vessels (TIVs) are essential for transporting and installing these large turbines. The construction time for wind turbines has increased due to their size and complexity, increased distance from the coast, and challenging weather conditions.

The cost of renting TIVs and other specialized vessels, ranging from USD 150,000 to USD 250,000 per day, is essential to the total project cost. The rental costs can escalate due to downtime caused by adverse weather conditions and unforeseen obstacles on the seabed. Typically, vessel rental and related work constitute about 10% of the total project cost, although this percentage can be higher depending on specific project conditions. Submarine power cables add to these costs at approximately 1 million euros per kilometer. Advancements in installation technology and improved project planning have reduced the overall costs associated with the installation phase.

Operation and Maintenance

Operation and maintenance run an additional USD 42,000- USD 48,000 per year. Traditionally, O&M costs have been categorized into operations, maintenance, and improvement activities. However, recent studies and practices have refined this categorization to reflect offshore wind operations' specific needs and challenges better.

Distribution of O&M Costs

The distribution of O&M costs is crucial for understanding the financial implications of maintaining offshore wind farms. Historically, operations accounted for approximately 20% of the total O&M costs. Strategic adjustments, such as reallocating 3% to life cycle management (LCM) and 6% to inspective maintenance, reduced the share of operations to 11%. LCM now encompasses maintenance scheduling and planning activities previously categorized under general maintenance, enhancing operational efficiency and minimizing downtime.

Find Global Offshore Wind Project and Tender LeadsClaim Your Free Leads!

Maintenance Types and Improvements

The bulk of O&M costs, traditionally around 80%, is attributed to maintenance activities. These are subdivided into inspective, preventive, and corrective maintenance. Inspective maintenance, recognized as a distinct maintenance type in recent studies, comprises 10% of the total O&M costs.

It involves regular inspections and assessments to identify potential issues before they escalate, thereby preventing costly breakdowns and ensuring continuous operational readiness. Adjusting the preventive/corrective maintenance ratio to approximately 1:3 underscores the importance of proactive maintenance strategies in minimizing operational disruptions and optimizing the lifespan of offshore wind infrastructure.

Improvement activities constitute another significant aspect of O&M costs, amounting to 25%. These include refits, major overhauls, and modification programs aimed at maintaining optimal performance and extending the operational life of wind farms. With the total O&M cost distribution ranging from 21 to 34 Euro/MWh, the emphasis on improvement activities reflects the industry's commitment to enhancing efficiency and reliability over the lifecycle of offshore wind assets.

Financing and Regulations

The finance options of offshore wind farm projects determine the viability and cost-effectiveness of offshore wind farm projects. In 2023, Europe witnessed a substantial increase in wind energy investments, particularly in offshore projects, amounting to EUR 48 billion. This surge was driven by record financing, reflecting improved investment climate benefits characterized by easing inflationary pressures, enhanced tariff indexation by governments, and greater certainty in electricity markets.

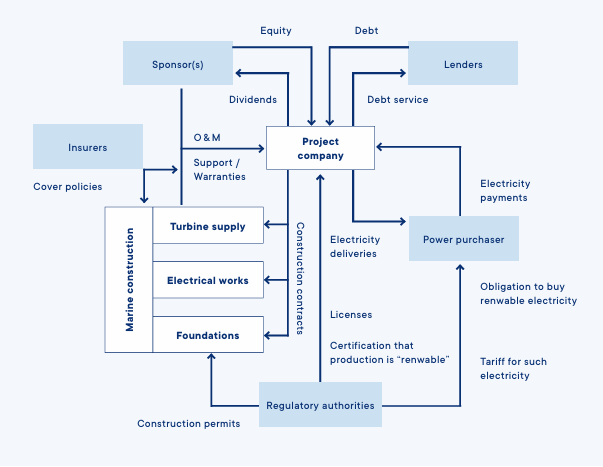

Contractual structure for an offshore wind project

Source: Green Giraffe

Financing of offshore wind farms

The average cost of offshore wind farms, estimated at EUR 1.1-1.2 million per megawatt of installed capacity, underscores the colossal initial investment required during construction.

Financing strategies for offshore wind projects typically involve a mix of sources, including bank loans, international financial institution funding, private placement of bonds, public issuance of bonds, leasing instruments, and government support. Bank loans, favored for their flexibility and risk-sharing attributes, provide long-term capital with maturity periods of up to 15 years post-construction.

International financial institutions contribute to funding energy projects that support regional prosperity, bolstering project credibility and attracting additional sources of capital. Private placement of bonds, offering fixed interest rates over extended periods, is prevalent in developed financial markets like the EU and the US, ensuring stable financing for long-term infrastructure projects.

Regulations

Regulatory frameworks and government policies also significantly influence the cost structure of offshore wind farms. Supportive regulatory environments and favorable government interventions are crucial in mitigating financial risks and attracting investments.

Policies such as feed-in tariffs, renewable energy certificates, and tax incentives incentivize private sector participation in renewable energy projects, reducing the overall cost of capital and enhancing project economics. Moreover, export credit agencies and strategic grants further alleviate financial burdens, supporting local offshore wind industry growth and technological innovation in offshore wind development.

Effective navigation of regulatory landscapes and alignment with evolving energy policies are imperative for optimizing project financing and ensuring cost competitiveness in the offshore wind sector.

Conclusion

Over the past decade, the decreasing cost of offshore wind farms can be attributed to advancements in turbine technology and size, favorable site conditions, streamlined construction and installation processes, efficient operation and maintenance strategies, and supportive financing coupled with regulatory frameworks. As these factors evolve and improve, offshore wind energy will become increasingly competitive and economically viable compared to fossil fuel alternatives. This will drive further adoption and sustainability in the global energy scenario.

FAQs

How much does it cost for a wind farm?

A wind farm with a capacity of 2-3 MW generally costs between USD 2 million and USD 4 million.

What is the cost of one windmill in India?

The cost of one windmill in India ranges between 4.5 crores to 5.5 crores.

How much do offshore wind turbines cost?

An offshore wind turbine costs USD 1,300,000 per megawatt.

How much does it cost to install an offshore wind farm?

An offshore wind farm with a capacity of 12 MW costs USD 400 million to manufacture and install.

What is the cost of 1 MW wind turbine in India?

A 1MW wind turbine in India costs between Rs. 5 to 5.5 crores.

Unlock Exclusive Insights into Global Offshore Wind Projects

Gain unparalleled access to our global offshore wind projects and tenders database. Subscribe for detailed project updates, key stakeholder contacts, and tailored business opportunities.

Start your free demo today and propel your business forward!

Leave a Comment

We love hearing from our readers and value your feedback. If you have any questions or comments about our content, feel free to leave a comment below.

We read every comment and do our best to respond to them all.