Table of Contents

Hydrogen has become one of the most widely used energy sources globally. The cost of the hydrogen plant setup depends on the production method, location, capacity, and technology used. For instance, the cost for blue or grey hydrogen plants varies from USD 500 to USD 1,000/ kg, whereas for green hydrogen plants, the estimated cost varies from USD 400 to USD 1500/kg h2.

In the past five years, the total investments across hydrogen projects have increased from USD 90 billion in 2020 to USD 680 billion in 2024. This growth is driven majorly by hydrogen projects in private sectors despite the increased inflation and interest rates.

From widely used grey hydrogen to emerging green hydrogen (clean energy), about USD 75 billion worth of projects have passed the FID stage and will be realized by 2030. Keep reading to understand the key factors that affect the hydrogen plant setup cost and how to calculate a hydrogen plant setup cost with examples.

Key Factors Affecting Hydrogen Plant Cost

The major factors that affect the hydrogen plant setup cost are hydrogen types, the production method used, location, capacity of the plant, and government-led incentives, subsidies, and tax breaks.

Hydrogen Types

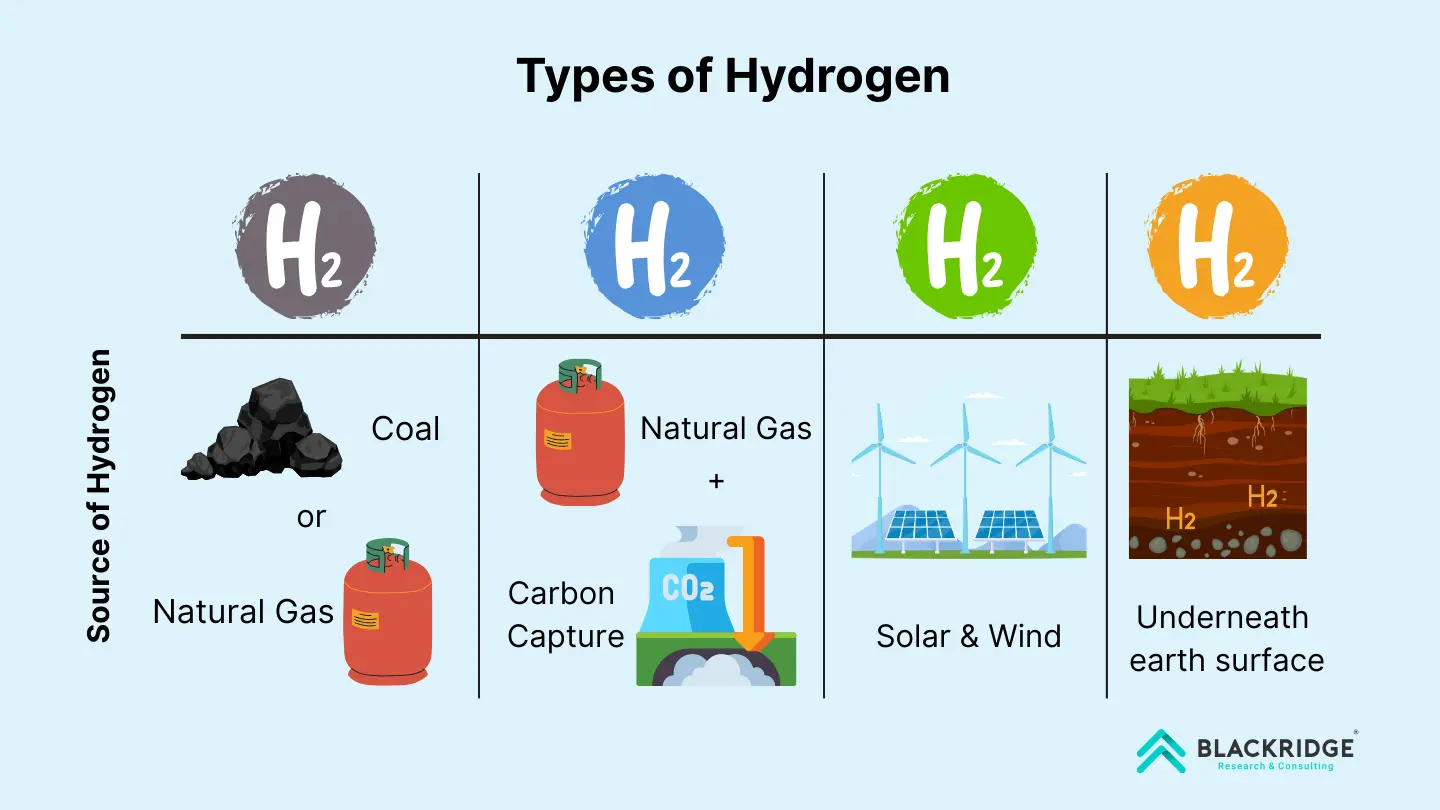

Hydrogen type plays an important role in determining the hydrogen plant cost. Let's explore the popularly known hydrogen types and how they impact the cost.

Grey Hydrogen: Grey hydrogen is the most popular and widely used hydrogen that is produced from coal and natural gas. It is affordable and has abundant sources but at a high environmental cost, resulting in high levels of carbon emissions.

Blue Hydrogen: Blue hydrogen produced from natural gas is as inexpensive and accessible as grey hydrogen. It is considered a better choice over grey hydrogen due to CCUS (Carbon Capture Utilization and Storage). This method captures and stores carbon emissions, reducing pollution and making it a better alternative to grey hydrogen.

Cost of Steam Methane Reformers

Steam Methane Reformers extract hydrogen from natural gas; the use of natural gas makes it affordable but has high carbon emissions. Using CCUS in blue hydrogen production increases the cost of plant setup, thus increasing production costs.

The cost of steam methane reformers varies with size and location; however, a standard steam methane reformer ranges from USD 1.25 to USD 3.50 per kilogram of hydrogen produced.

Cost of Natural Gas

| Global Gas Benchmark | Pricing (USD per mmBtu) | Region |

|---|---|---|

| Henry Hub | 4.11-4.15 | North America |

| Title Transfer Facility (TTF) | 13.6 | Netherlands |

| Japan Korea Marker (JKM) | 13.11 | Japan and South Korea |

*metric million British thermal units

Green Hydrogen: Green hydrogen is emerging and unique, produced using renewables like solar and wind. It is a clean hydrogen with zero carbon emissions, making it the best alternative. However, the challenge of high costs involved in sourcing and setting up renewable plants to power electrolysis for green hydrogen production.

Geological Hydrogen: Also known as gold hydrogen or the natural hydrogen, it is a naturally occurring hydrogen found in the Earth's crust. Unlike the other hydrogen types, this white hydrogen is naturally formed in underground reservoirs, often in ultramafic rock formations or oil & gas fields. It can be extracted in a way similar to oil or natural gas. However, its extraction and exploration costs are high, and the long-term availability of large reserves is still uncertain.

Location

The location of the hydrogen plant is a key factor influencing hydrogen plant setup cost. Factors such as the availability of fossil fuels, renewable energy sources, and location affect the costs. Let us understand how location impacts the cost and compare hydrogen plant costs across different countries.

- Regions like the Middle East, Australia, and India receive maximum solar irradiation and have low solar plant installation costs, thus lowering the cost of green hydrogen production.

- Coastal areas with strong winds, such as Europe, the US, and China, have solar and wind-powered hydrogen plants.

- Countries like the US and Russia are known for their surplus natural gas reserves that help them produce grey and blue hydrogen.

Also Read: Green Hydrogen Plant Setup Cost in India

Government Policies and Incentives

Several countries are initiating incentives and policies promoting global hydrogen projects.

North America

- North America leads the low-carbon hydrogen (Blue hydrogen-based plants) due to financial incentives like the IRA 45Q tax credit.

- The National Clean Hydrogen Strategy and Roadmap is planned through 2025, mid-term to 2029, and until 2035. Under this, the US envisions producing 10 MMT annually by 2030, 20 MMT by 2040, and 50 MMT by 2050.

Latin America

The availability of low-cost renewables leads to cheaper hydrogen production. However, infrastructure investment is a challenge. Thus, countries like Chile and Brazil are focusing on export-oriented green hydrogen projects.

India

India launched its “National Green Hydrogen Mission,” which targets the development of green hydrogen infrastructure to produce 5 MMT of green hydrogen annually and increases the renewable energy capacity to 125 GW. Under this mission, several other targets are launched, such as:

- Financial incentives of INR 8 lakh crore (USD 96 billion)

- 6 lakh job opportunities will be created during this mission

- The overall reduction in fossil fuel usage of over INR 1 lakh crore

- Abatement of 50 MMT carbon emissions annually

Also Read: Green Hydrogen Policy 2024: What You Need to Know

Understanding these factors is essential; however, let’s break down the step-by-step process of estimating the cost of a hydrogen plant.

How to Calculate Hydrogen Plant Cost?

Calculating the total cost of a hydrogen plant requires analyzing two main components: the CapEx (capital expenditure) and OpEx (Operational Expenditure).

Step 1: Decide the hydrogen type and Location

Step 2: Decide the plant capacity and the technology(electrolysis, steam processing)

Step 3: Calculate the CAPEX. The CAPEX includes electrolyzer cost, renewable energy cost (solar/wind plant setup)

Capital Expenditure (CapEx)

The Capex is calculated based on several factors such as the electrolyzer types, the sources of energy, storage system, piping & distribution, and land & civil engineering costs. Below is a detailed explanation of the CapEx cost breakdown.

Capex= electrolyzer cost+ renewable energy setup cost + storage & distribution cost

Electrolyzer cost calculation = Electrolyzer price/capacity in MW

For example, if you are planning to install a 50 MW capacity, and an alkaline electrolyzer costs 1 million per MW, then the cost of the electrolyzer will be 50*1 = 50 million.

Renewable Energy Setup Cost = Solar/Wind Farm Cost per MW × MW Capacity

Storage & Distribution Cost = Storage Facility + Transportation Infrastructure

Operational Costs (Opex)

Electricity Cost = Power Cost per kWh × Energy Used

Maintenance Cost = % of Total CapEx

For example, if the cost of electricity is USD 0.04 per kWh and if the plant requires 300,000 kWh per day, the electricity cost per day is USD 12,000.

Step 4: Add the CapEx and OPEX for an estimated hydrogen plant cost.

Example Estimate of a Green Hydrogen Plant Cost

Suppose you are building a 50-MW alkaline electrolyzer-powered green hydrogen plant in Europe. To calculate the CapEx, we require the electrolyzer cost, renewable energy setup cost, and storage & distribution cost.

Electrolyzer Type

The electrolyzer type plays a huge role in the setup and production of green hydrogen. There are four types of hydrogen electrolyzers:

| Electrolyzer | Electrolyte Type | Usage |

|---|---|---|

| Polymer Electrolyte Membrane Electrolyzers (PEM) electrolyzers | Solid polymer membrane | FCEV (Fuel Cell Electric Vehicles) and energy storage |

| Alkaline electrolyzers | Alkaline Exchange Membranes (AEM) (NaOH) | Green hydrogen production and energy storage |

| Solid Oxide Electrolyzer Cells (SOEC) | Solid ceramic material | High-temperature hydrogen production |

| Anion Exchange Membrane (AEM) Electrolyzer | Semi-permeable membrane | Low-cost hydrogen production. |

Alkaline Electrolyzers are one of the most widely used electrolyzers due to their low cost and higher efficiency. The reason is alkaline technology uses cheaper materials such as nickel and electrodes, whereas the next best alternative, the PEM electrolyzer uses metals like iridium, which make it an expensive electrolyzer.

Electrolyzer Cost Estimation Table

Below is a table that estimates electrolyzer costs in different countries based on their type as of 2024.

| CapEx in USD million | ||||

| Region | Alkaline | PEM | SOEC | Other |

| Europe | 1.08 | 1.245 | 3 | 3 |

| China | 0.8 | 0 | 3 | 3 |

| North America | 1 | 0 | 3 | 3 |

| Rest of the World | 1 | 0 | 3 | 3 |

Source: Blackridge Research hydrogen database

How this pricing influences the overall plant cost

In countries like China, the popularly used alkaline electrolyzer is USD 0.8 million, which reduces the entire cost of green hydrogen production. i.e., the cost of the electrolyzer is directly proportional to the cost of the green hydrogen production. Countries like North America and other companies have an alkaline electrolyzer at USD 1 million, whereas Europe has an electrolyzer capacity around USD 1.08 million.

Example: cost of electrolyzer: 1.08* 50 MW = 54 million.

Storage & Distribution Costs

Storage & Distribution of hydrogen is one of the major factors in the CapEx. Hydrogen is known to have a low density and high flammability. To store and distribute hydrogen, hydrogen must be compressed and converted into liquid hydrogen or ammonia-based hydrogen.

Conclusion

Calculating the setup cost of a hydrogen plant includes several factors, such as the hydrogen type, capacity, location, technology, and many more. The grey and blue hydrogen plant setup is considered cheaper due to the use of natural gas as a primary source. In contrast, the production of green hydrogen is relatively expensive due to renewable energy sources like solar or wind. The plant's location can impact the overall hydrogen plant setup cost, as some places have more sun or natural gas, which can lower costs. Additionally, the government's tax breaks, policies, and incentives help reduce the setup cost.

The type of electrolyzer and hydrogen production process also affects the initial capital expenditure (Capex), with alkaline electrolyzer typically being more cost-effective than PEM or SOEC technologies. The operational costs of the plant, such as electricity, hydrogen storage, and distribution, also affect the total plant cost, which requires compression or liquefaction of hydrogen. As the hydrogen industry continues to expand, the setup and production costs are influenced by several global and economic factors.

Explore Business Opportunities in Green Hydrogen Projects Worth $3 trillion Across the Globe!

Subscribe to our Global Green Hydrogen projects database and receive exclusive benefits like:

- Regular updates on green hydrogen projects and tenders

- Essential details, timely updates, key stakeholder contact information

- Industry trends and insights by experts

Claim your free projects by subscribing to the Global Green Hydrogen projects database to take your business to the next level!

Leave a Comment

We love hearing from our readers and value your feedback. If you have any questions or comments about our content, feel free to leave a comment below.

We read every comment and do our best to respond to them all.