Table of Contents

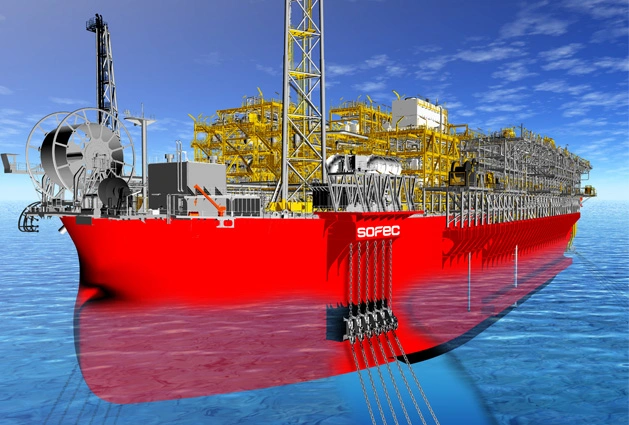

An FPSO (Floating Production, Storage, and Offloading) vessel processes oil and gas by receiving hydrocarbons from underwater wells, using topside modules for separation and treatment, storing the processed oil in its hull, and offloading it to shuttle tankers for transport to shore.

When the oil reaches a specific capacity, it is offloaded onto shuttle tankers or other transport vessels. FPSOs also have utilities and support systems, such as power generation and dynamic positioning systems.

But FPSOs aren't just about extracting resources from the ocean; they represent a pivotal shift towards sustainability and innovation in the energy sector. This blog provides an in-depth understanding of how FPSO works from hull to topside modules and their role in shaping the future of energy.

Hull Design and Construction

The hull of an FPSO vessel refers to the main structural component that provides buoyancy and stability to the entire vessel. The hull serves as the watertight outer shell of the FPSO, designed to withstand the forces of the ocean environment, including waves, currents, and wind.

Components of the hull and their functions

The hull of an FPSO (Floating Production Storage and Offloading) vessel is a complex structure comprising various components, each serving a specific function to ensure the vessel's stability, buoyancy, and overall structural integrity. Here are some of the key components of an FPSO hull and their functions:

Main Structural Framework: The main structural framework of the hull consists of steel plates welded together to form the basic shape of the vessel. This framework provides the structural integrity and strength necessary to withstand the forces encountered at sea, including waves, currents, and wind.

Ballast Tanks: Ballast tanks are compartments located within the hull that can be filled with water or emptied to adjust the vessel's trim and stability. By changing the distribution of weight within the hull, ballast tanks help maintain the FPSO's stability in varying sea conditions.

Find FPSO Projects and Tender Leads around the Globe Claim Your Free Leads!

Storage Tanks: The hull of an FPSO typically includes storage tanks for holding processed oil, water, and other fluids produced during offshore operations. These storage tanks are usually located in the lower portion of the hull to minimize the vessel's center of gravity and enhance stability.

Machinery Spaces: Machinery spaces are compartments within the hull where the vessel's propulsion systems, generators, pumps, and other essential equipment are housed. These spaces are designed to accommodate the machinery required to operate the FPSO safely and efficiently.

Bulkheads and Decks: Bulkheads are watertight partitions that divide the hull into separate compartments, providing structural reinforcement and preventing the spread of water in the event of a breach. Decks are horizontal platforms within the hull that provide access to different areas of the vessel and support topside modules and equipment.

Mooring System Attachments: The hull of an FPSO is equipped with attachment points and anchor chains or mooring lines to secure the vessel to the seabed. The mooring system is essential for maintaining the FPSO's position and preventing drift during offshore operations.

Cathodic Protection Systems: FPSO hulls are often equipped with cathodic protection systems to prevent corrosion and prolong the lifespan of the vessel. These systems use sacrificial anodes or impressed currents to protect the steel structure of the hull from the corrosive effects of seawater.

Construction of an FPSO hull

The construction of a FPSO hull involves several stages, starting with the initial design and engineering phase. This involves naval architects and marine engineers developing detailed plans and specifications, including structural analysis, stability calculations, and feasibility studies.

Once the design is finalized, materials like steel plates and beams are procured from suppliers to ensure the vessel's integrity and strength. The hull is then fabricated, a process which involves cutting, shaping, and welding steel plates according to the design specifications.

The hull is then assembled into large blocks, which are prefabricated on land and assembled in dry docks or construction berths.

After the hull blocks are assembled, outfitting and equipment installation take place, including machinery, piping systems, electrical systems, and topside modules. Finally, the FPSO undergoes rigorous testing and commissioning to ensure the proper functioning of all systems and components.

FPSO Topsides Modules

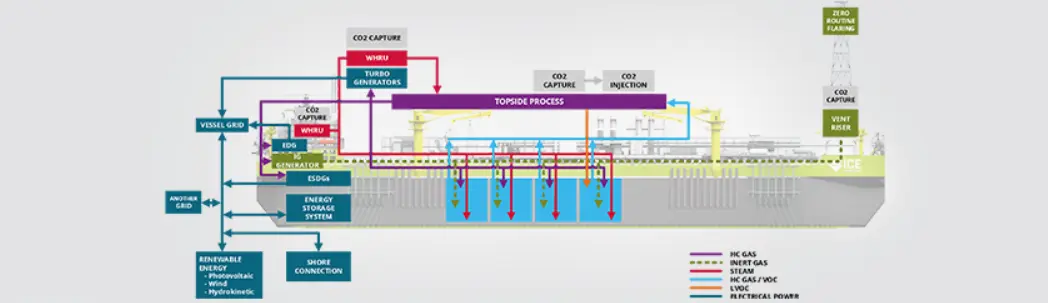

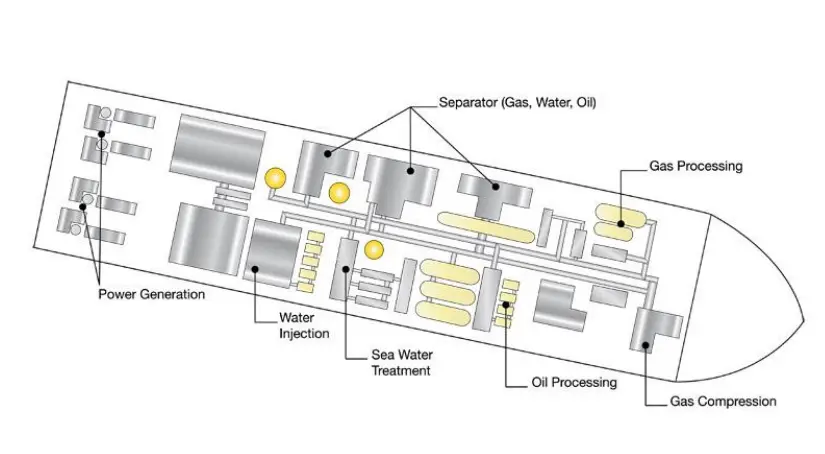

The FPSO topside process facility is designed to receive a full well stream from production risers and separate gas, water, and crude oil. Stabilized oil is stored in hull storage tanks, while treated water is discharged overboard. Compressed and treated gas is used for gas reinjection and fuel gas consumption.

Seawater is lifted, filtered, and distributed for heat exchange, freshwater production, de-aeration, and sulfate removal for water injection. This separation process ensures efficient and safe operations.

Various modules and their functions

Here's a breakdown of various topside modules found on an FPSO and their respective functions:

Crude Separation Module: This module separates crude oil from water and gas using components like a sand filter, slug catcher, and production separator.

Crude Stabilization Module: Essential for stabilizing crude oil by removing impurities, it includes an electrostatic coalescer, LP separator, and LLP separator.

Crude Oil Storage and Offloading System: This system facilitates the storage and offloading of crude oil, featuring an oil cooler and storage tank.

Water Treatment Module: Responsible for cleaning produced water to meet environmental regulations, it effectively removes impurities and separates oil.

Gas Treatment Module: Designed to clean associated gas, this module involves gas compression, dehydration, and impurity removal processes.

Read: FPSO vs. FSO: Understanding the Key Differences and Applications

Fuel Gas Treatment Module: Ensures compliance with air emission regulations by preparing fuel gas for burning.

H2S Removal Module: This module removes hydrogen sulfide (H2S) from gas streams to enhance safety.

Flare System: Safely burns off excess gas during emergencies or maintenance procedures.

Lift Gas Compression Module: It compresses gas for injection into oil wells to enhance production efficiency.

Produced Water Treatment Module: Cleans produced water to meet discharge standards, effectively removing oil, solids, and contaminants.

Heat Medium Module: Manages heat transfer within the system to optimize operational efficiency.

Desalter Module: Removes salt and impurities from crude oil, ensuring high-quality output.

Separation Module: Efficiently separates gas, oil, and water streams to enhance production effectively.

Importance of topside modules in FPSO operations

Topside modules are essential components of FPSO operations, providing the infrastructure and facilities necessary for safe, efficient, and environmentally responsible production and processing of hydrocarbons offshore. Their integration, functionality, and reliability are critical factors in the success of FPSO projects and the overall sustainability of offshore oil and gas operations.

Production Processing: Topside modules contain equipment for the separation, processing, and treatment of hydrocarbons produced from subsea wells. This processing is essential for separating oil, gas, and water efficiently, ensuring that the extracted hydrocarbons meet quality standards for storage and offloading.

Safety and Environmental Compliance: Many topside modules are dedicated to safety systems and environmental compliance. These modules ensure that FPSO operations adhere to stringent safety regulations and environmental standards, reducing the risk of accidents, spills, and harm to the environment.

Storage and Offloading: Topside modules include facilities for storing processed crude oil and other hydrocarbons. This storage capacity allows FPSOs to accumulate oil over time before offloading it onto tankers for transportation to refineries or other destinations.

Utility Services: Topside modules house utility systems that provide essential services such as power generation, water treatment, and HVAC (heating, ventilation, and air conditioning). These services are critical for maintaining a comfortable and safe working environment for FPSO personnel and ensuring the smooth operation of production facilities.

Find FPSO Projects and Tender

Leads around the Globe Claim Your Free Leads!

Control and Monitoring: Topside modules typically contain control rooms equipped with instrumentation and monitoring systems for overseeing and managing FPSO operations. Operators use these systems to monitor equipment performance, control production processes, and respond to operational events in real time, ensuring optimal production efficiency and safety.

Flexibility and Adaptability: Topside modules are often designed to be modular, allowing for flexibility in configuration and easy adaptation to changing production requirements.

This modularity enables operators to modify and upgrade FPSO facilities as needed to accommodate new reservoirs, production techniques, or regulatory requirements, extending the operational life of the FPSO.

Mooring system in FPSO

A mooring system refers to the arrangement of components used to secure an FPSO vessel to the seabed during offshore operations. It consists of anchor points deployed on the seabed, mooring lines or chains connecting the FPSO to these anchors, and associated equipment for deployment, tensioning, and maintenance.

Types of Mooring Systems Used in FPSOs

FPSO Spread Mooring System: In this system, multiple anchor points are spread around the FPSO, and mooring lines are attached directly to the vessel's hull. Spread mooring systems are commonly used in shallow to moderate water depths.

Turret Mooring System: A turret is installed at the center of the FPSO, allowing it to rotate with changes in wind, waves, and currents. Mooring lines are connected to the turret, providing flexibility and allowing the vessel to weathervane. Turret mooring systems are suitable for deeper water depths and harsh environmental conditions.

Single-Point Mooring System: Also known as a single-point mooring (SPM) or single buoy mooring (SBM) system, this setup involves a single anchor point on the seabed, with a buoy or turret at the surface to which the FPSO is connected. Single-point mooring systems are often used for offloading purposes in deepwater locations.

Importance of a Reliable Mooring System

Safety and Stability: A reliable mooring system is crucial for maintaining the stability and safety of the FPSO during offshore operations. It prevents the vessel from drifting and ensures it remains in position, even in adverse weather conditions.

Operational Continuity: A robust mooring system minimizes the risk of downtime and interruptions to production operations. It allows for continuous production and offloading of hydrocarbons from offshore oil fields, maximizing operational efficiency and profitability.

Looking for Global FPSO Market Report? Download Sample Report Now!

Environmental Protection: A secure mooring system helps prevent accidents such as collisions or spills, minimizing the risk of environmental damage in sensitive offshore ecosystems. It ensures compliance with environmental regulations and promotes sustainable offshore oil and gas operations.

Water Depth Adaptability: Different types of mooring systems are designed to accommodate varying water depths and environmental conditions. A reliable mooring system provides flexibility and adaptability, allowing FPSOs to operate effectively in shallow, moderate, and deep water offshore oil fields.

Offloading Systems

Offloading systems are critical for the successful operation of FPSOs, enabling the efficient and safe transfer of hydrocarbons from offshore oil fields to refineries or other destinations. The selection of offloading systems depends on factors such as water depth, environmental conditions, operational requirements, and cost considerations. Let’s explore the offloading systems used in FPSOS:

Tandem Offloading

- In tandem offloading, an FPSO transfers oil to a shuttle tanker while both vessels remain connected.

- The FPSO and the shuttle tanker are held in position by dynamic positioning systems.

- This method is efficient and allows continuous production and offloading.

Side-by-Side Offloading

- In side-by-side offloading, the FPSO and the tanker are positioned alongside each other.

- They maintain a fixed distance, and hoses or loading arms connect them.

- This method is commonly used for LNG (liquefied natural gas) transfer.

Submerged Turret Loading (STL)

- The STL system features a turret swivel at the bow of the FPSO.

- The shuttle tanker connects to the turret via a flexible hose.

- The turret allows the FPSO to weathervane (rotate) freely with changing wind and wave directions.

- STL is widely used due to its flexibility and reliability.

Future trends and innovations in the offshore gas and oil industry

The offshore oil and gas industry is experiencing significant transformations driven by digitalization, automation, and advancements in subsea technology. These changes are revolutionizing operations and opening doors to new opportunities and challenges.

Digital technologies such as IoT, Artificial Intelligence, and advanced analytics are playing a crucial role in streamlining operations, cutting costs, and reducing human errors. Meanwhile, advancements in subsea technology, including robotics and remotely operated vehicles, are enabling deeper exploration and production in challenging offshore environments.

Efforts are also being made towards decommissioning strategies and asset integrity management to ensure safety and environmental protection. Moreover, the industry is diversifying towards renewable energy sources such as offshore wind and marine energy, as well as exploring carbon capture and storage (CCS) technologies to combat climate change.

Offshore platforms are now being utilized as hubs for hydrogen production, offering clean energy alternatives and contributing to decarbonization efforts. This diversification and integration of renewable energy sources signify a shift towards sustainability and environmental responsibility in the offshore oil and gas sector.

Conclusion

FPSOs are complex structures designed for specific functions like production, storage, and offloading of hydrocarbons. The discussion focused on FPSOs, detailing their design, construction, and operation from the hull to the topside modules. The importance of FPSOs in the offshore oil and gas industry is emphasizing their role in sustainable energy production and innovation.

The in-depth explanation of the hull parts, building process, topside modules, mooring systems, and their roles shows how complicated and important FPSOs are for getting and processing hydrocarbons offshore. In the future, the oil and gas sector will move towards sustainable energy solutions by integrating technology to meet the increasing demand for renewable energy sources.

Looking for more than generic information on FPSO vessels around the Globe?

Subscribe to our Global FPSO & FSO (Oil & Gas) Projects and Tender Database to access reliable and high-quality insights on upcoming, in-progress, and completed floating offshore plant projects across the world or in your desired location.

Our user-friendly platform provides essential details, timely updates, key stakeholder contact information, and business opportunities tailored for engineering companies, industry professionals, investors, and government agencies.

Start a free demo to take your business to the next level!

![Top FPSO Companies in India [2025]](https://images.blackridgeresearch.com/zA7C1E09-z4Uj64Eb0zfkw/fef13aed-1db8-4a25-bf1c-ffc0ed743a00/public)

Leave a Comment

We love hearing from our readers and value your feedback. If you have any questions or comments about our content, feel free to leave a comment below.

We read every comment and do our best to respond to them all.